Solid Bamboo VS Strand Woven Bamboo

Bamboo has been used to make rudimentary floors for centuries. However, it bursts onto the commercial market in the 1990s, and its popularity has been growing ever since.

In modern flooring market, bamboo is generally processed in two ways, solid bamboo and strand woven bamboo, each with their own unique set of benefits. And whether to choose solid or strand woven bamboo may be a question you are thinking about.

What is the difference between solid and strand woven bamboo?

There are three main differences, as below shows:

1. Manufacturing Process & Appearance

The main difference between solid and strand woven bamboo is the way that the planks have been constructed.

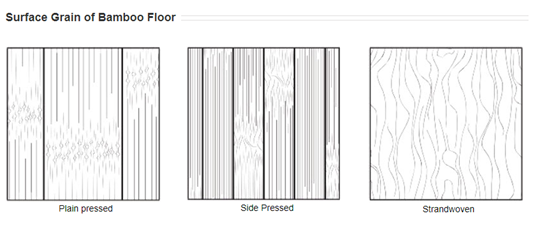

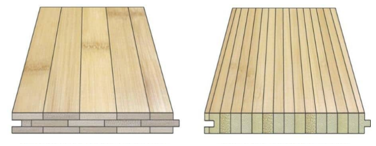

Solid bamboo is made from strips of bamboo that have been dried and glued together and then compressed to form a plank of flooring. There are normally two layouts, horizontal (plain pressed) and vertical (side pressed). For horizontal type, the strips are laid flat, one top the other. This results in a floor with fewer features and a more consistent look. It is also the closest match to the actual appearance of natural bamboo materials. For vertical type, the strips are lined up, straight up and down, and are bonded with pressure applied from both sides. The result is still a natural bamboo look, which tends to have more mottled, busy features on their surface.

Strand woven bamboo is made purely from bamboo fibers that have been compressed together with glue to form the planks of flooring. It lost the appearance of traditional bamboo because it’s compressed, and more like wood. There are two pressing method of strand woven bamboo, cold pressing and hot pressing. Cold pressing normally with less investment in equipment, but with limited width size. And the manufacturing technique will easily cause the problems like cracking and deformation on the flooring surface. Hot pressing can provide a wider panel size, but requires a much higher investment in equipment. Under as high as 2700tons hot pressing to achieve an uniform density, the bamboo board is more durable and stable for outdoor application.

2. Density & Durability

Because of different manufacturing process, the density of solid bamboo is normally 650kg/m3, while strand woven bamboo can reach around 1200kg/m3, almost double as solid bamboo. To fully integrates the adhesive with the bamboo, and more adhesive is used by a percentage of weight, strand-woven material tend to be considerably harder and more durable than solid vertical-grain or horizontal-grain bamboo.

3. Application

Both solid bamboo and strand woven bamboo are dimensionally stable, and can be widely used in hotels, villas, clubs, office buildings, shopping malls, theaters, sports venues, amusement venues and other fields. Solid bamboo turns to be more suitable for indoor application, while strand-woven bamboo can be used both indoor and outdoor, mostly used for outdoor decking for its anti-decay, water proof and high weather resistance characteristic.

Bamboo has proven to be a versatile and functional floor choice. However, understanding some basics of the construction process can help you make the right choice from the start.