How is strand woven bamboo decking made?

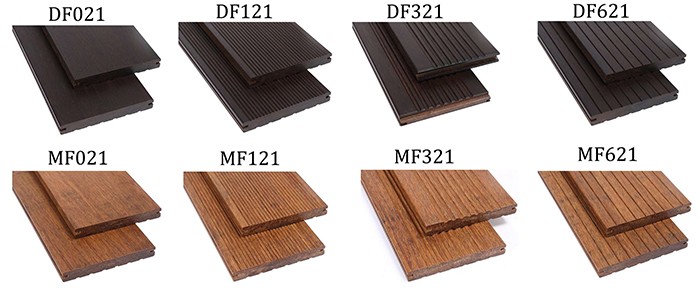

REBO strand woven bamboo decking is high density and performed durability Class 1 (EN350), use class 4, fire proof, water proof, anti-mildew, anti-corrosion and anti-slip. The color can be dark (deep carbonization) and brown (medium carbonization).

Strand woven bamboo decking is made by compressing bamboo fibers under extreme heat and pressure, which gives strand woven bamboo decking great strength and durability.

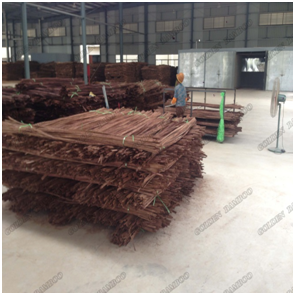

After the bamboo has been harvested, REBO will select bamboo with age more than 5 years. The bamboo pillars' diameter should be more than 10cm and the bamboo wall thickness is about 7mm.

The bamboo pillars will be classified by the thickness, and will be cut to required length.

The external skins and internal skins of bamboo strips will be removed. The bamboo fibers are kept for production.

The bamboo strips will be smashed to reticular fiber evenly. The size of fibers will be 2-3mm.

The smashed bamboo fibers will be carbonized by high temperature. The carbonization will remove the sugar and protein in the bamboo. The worms and fungi in the bamboo will be killed at the same time.

The moisture content of carbonized bamboo fibers should be less than 12% to absorb glue, so drying in baking room is very necessary.

REBO strand woven bamboo fibers are glued with Dynea glue, which is known as the No. 1 glue brand in the world.

After soaking with glue, it is important to control the moisture content in range of 12-15%. REBO will put bamboo fibers together to balance the moisture for one week.

The glued bamboo fibers will be hot pressed by 2700 tons pressing machine. The smashed bamboo fibers are totally mixed with the Dynea resin and pressed to be strong panels, which is much stronger than traditional woods.

The bamboo panels will be put together to balance for 15 days so that the moisture, resin and bamboo fibers can integrate better.

The bamboo panels will be cut to specific sizes and certain designs.

REBO bamboo decking is pre-finished with Woca brand water-base oil. The long painting production line can remove dust, oil, dry panels, oil again and dry again in one time. The oiled panels have longer service life than plank panels.

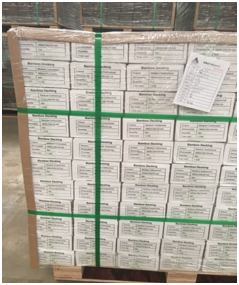

The products are usually packed by pallets, sometimes with cartons required by the customers.

REBO bamboo is applied at urban landscape, hotel engineering, villa decoration, building materials supermarket, horse stable, etc. The business has now covered more than 30 countries and regions such as Europe, America and the Middle East, which advocate green, environmental protection and health concepts.