Comparison of Cold Pressing and Hot Pressing Strand Woven Bamboo

Strand woven bamboo, also known as compressed-strand bamboo, is considered as one of the most popular flooring choice for both commercial and residential buildings, due to its attractive pattern, matchless durability, great looks and easy to maintain. They can be found in malls, restaurants and anywhere large groups of people congregate on a regular basis, and popular for private house too, by providing a richness and depth to a living space.

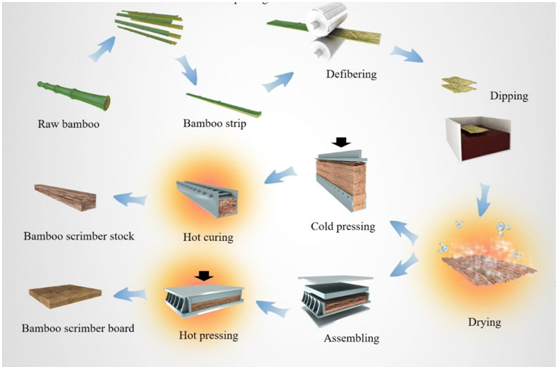

There are two manufacturing methods of strand woven bamboo, that is cold pressing and hot pressing.

What the difference between cold pressing and hot pressing?

Cold pressing is a kind of block pressing. By loading the bamboo fibers into the mold, about 150 x 150 mm in width and height. Then the mold is locked and heated slowly in an attempt to ‘cook’ the bamboo through to the centre of this block. During the heating process, the mold will become expansion, thus cause an uneven density. The density of the edge part is always lower than the middle part. The cold is basically forming a square material, and the moisture content is around 10-12%, which may result in warping in dry places and where under floor heating is used.

Hot pressing is big panel pressing. Laying the bamboo fibers in the big press form, which around 1290mm width, under a pressure of thousands of tons to forming. The pressure heating and curing is done and completed at the same time, so the pressure spreads more evenly on the big board to achieve an uniform density, and the moisture content is more easier to be controlled around 8%-10%.

Here below are the pictures of both manufacturing process for your better idea.

Which kind is better?

Each technology has its own advantages and disadvantages. Here below are the pros and cons for your better understanding.

Cold Press

Pros: 1.Cold-press has a long curing time, which may with a less color variation on the floor surface.

2. Cutting process is simple.

3. Lower equipment investment, higher production efficiency, and thus a lower cost.

Cons: 1. Uneven board density. This will result in problems, like collapse, cracking and deformation on the floor surface.

2. With limited board size, the max. width is 140mm.

Hot Press

Pros: 1. Uniform density, with a better sustainability and durability guaranteed.

2. A wider board size option. The width of big board is 1290mm, and then cut into different small sizes.

Cons: 1. A shorter heat curing time, so with a relative larger color variation than cold version.

2. With higher density, it is more difficult to cut.

3. Higher equipment investment, a higher cost.

In a word, hot-pressed strand woven bamboo costs more, but ultimately will prove to be the longest lasting of outside building, like outdoor terrace, wall cladding and fencing. And cold -pressed strand woven bamboo will be more suitable for indoor bamboo flooring, ceiling. So whether to choose hot-pressed or cold-pressed bamboo, it depends on the application.